I. Core Features

1. Attributes: High-precision fine powder screening equipment with advantages of low noise and high efficiency.

2. Convenience: Quick screen replacement takes only 3-5 minutes.

3. Core Advantages: Long material travel trajectory, high screen surface utilization, enabling fine and probability screening of materials.

II. Working Principle

1. Power Source Configuration: A vertical motor is used as the excitation source, with eccentric blocks installed at both ends of the motor.

2. Motion Form Conversion: Through the upper and lower eccentric blocks, the rotational motion of the motor is converted into a three-dimensional composite motion of horizontal, vertical, and inclined directions, and this motion is transmitted to the screen surface.

3. Material Motion Generation: The three-dimensional motion of the screen surface causes the material to move involutely on it, providing the basis for screening.

4. Screening Process Implementation:

When the motor runs at high speed, the upper and lower eccentric blocks at different phases generate a composite inertial force, driving the screen box and screen surface to vibrate periodically.

The material on the screen surface moves directionally with the screen box. Material smaller than the screen aperture falls to the lower layer (undersize), while material larger than the screen aperture is discharged from the discharge port after continuous jumping (oversize), completing the screening process.

5. Motion Trajectory Adjustment: By adjusting the relative phase angle of the eccentric blocks at the upper and lower ends of the motor, the motion trajectory of the material on the screen surface can be changed to adapt to different screening requirements.

6. Vibration Trajectory Characteristics: The spatial trajectory of the equipment's vibrating body is a complex three-dimensional curve. Its horizontal projection is a circle, and its vertical projection is two identical ellipses.

Features

1. It is suitable for the separation of 10-200 micron materials that are difficult to sieve, and the sieving can reach 800 meshes

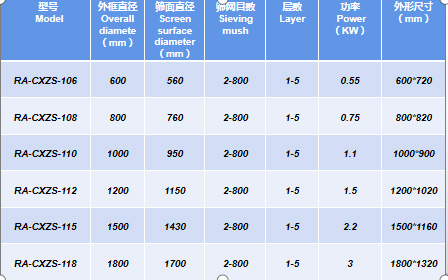

2. According to the material screening requirements. Configure 1 to 5 layers of sieves with different mesh numbers

3. The circumference of the discharge port is designed, and the position can be set at will, which is convenient for production

4. Modular structure, fast loading and unloading and cleaning

5. Make the separation of materials with special properties simple, and do not change the characteristics of the materials, suitable for new materials

6. The elastic ball or ultrasonic cleaning device can effectively prevent the mesh from clogging or similar poor impaction, and prolong the service life of the screen.

7. Low and stable operating temperature, will not make the local temperature higher, can work continuously

8. The foundation does not need special treatment, and the required area is small

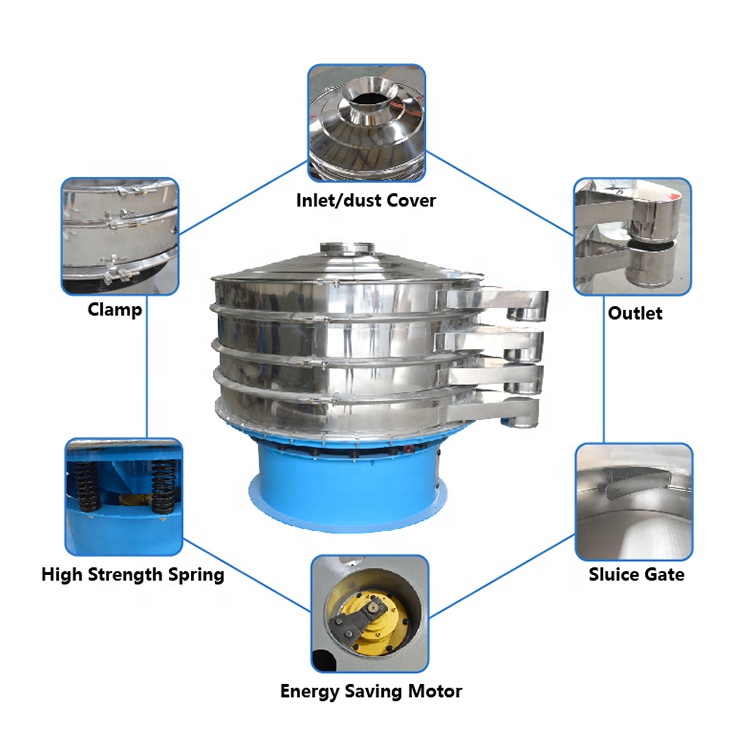

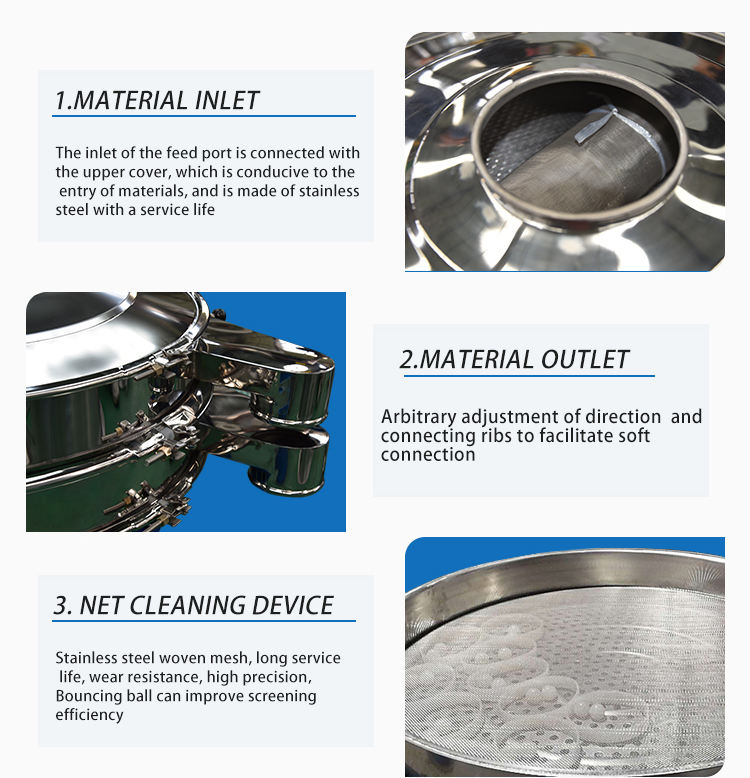

Equipment Details

Equipment Parameters

Engineering case1

Zhejiang **** Co., Ltd.

Screening material Matcha powder Material specific gravity 0.3 Screening 80 mesh One hour output 130KG RA-CXZS Ruang rotary vibrating screen series can easily solve screening problems for customers.

Engineering case2

Chemical Industry Screening

Jiangsu **** Co., Ltd.

Screening material Magnesium oxide Material specific gravity 1.1 Screening 300 meshes Single unit one hour output 160KG RA-CXZS Ruang rotary vibrating screen series can easily solve screening problems for customers.