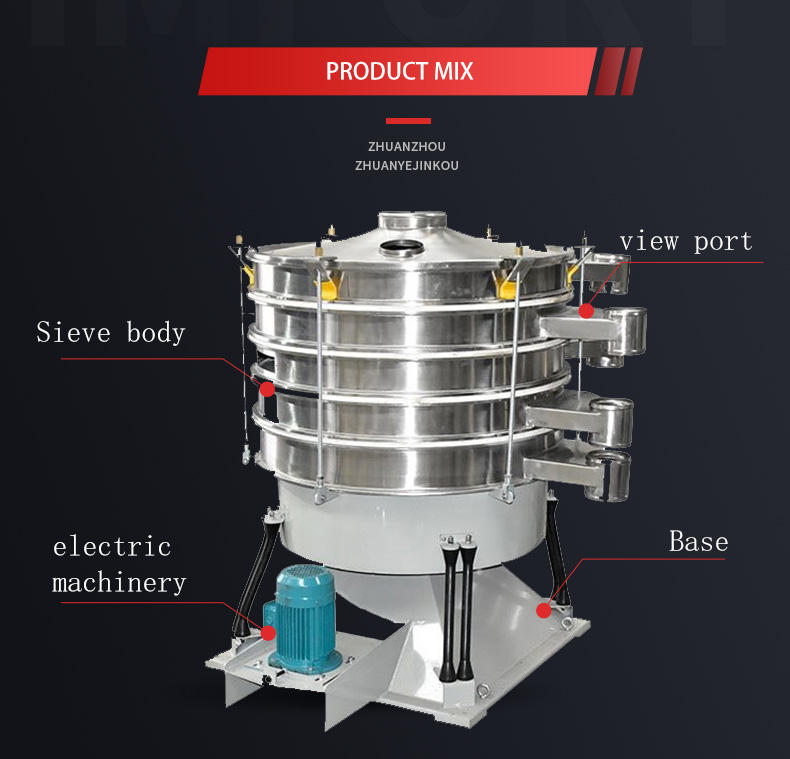

Tumbler screen is a low-frequency rotary vibrating screen that directly imitates manual screening. Its motion trajectory is the combination of radial displacement of instantaneous motion and circular motion with this displacement as the axis. Nonlinear three-dimensional motion can be generated by adjusting the eccentricity of the vibration exciter. The motion mode of materials on the screen surface is similar to manual screening, so as to achieve the effect of screening materials. The screen body is equipped with a unique screen cleaning device, so as to achieve effective screening effect, especially suitable for the precision screening of cylindrical, sheet and other irregular materials.

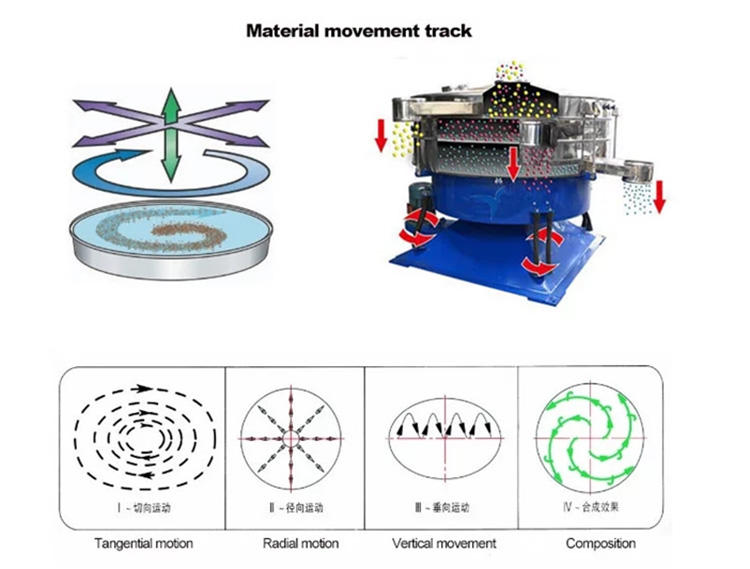

Working Principle

Tumbler screen is a kind of low-frequency rotary vibrating screen imitating manual shaking. Its principle is: the instantaneous motion is the synthesis of radial displacement and circular motion with this displacement as the axis (spiral motion). The vibration exciter with adjustable eccentricity produces nonlinear three-dimensional motion, and the material also produces the same motion similar to manual operation,so as to achieve the purpose of screening.

Product Features

Single layer or multi-layer high-efficiency screening can be realized, and 6 particle sizes can be screened. Up to 5 layers, while providing 5 to 6 groups of grading.

The principle of swing screen is actually a mechanical simulation of manual screen. Gentle acceleration and low-speed operation ensure that the material rolls on the surface of the screen. Especially for dry, low-density particles; It can also effectively reduce the wear of high abrasive products on the screen itself (screen).

Each layer of screen realizes accurate grading of coarse and fine particles. The materials are fed from the center of the horizontal screen body and diverge to the periphery along the spiral curve. At the same time, with the increase of vertical acceleration, the fine-grained products are forced to pass through the screen surface effectively.

It can effectively reduce the damage of fragile materials, and the hand screen can give mild treatment to materials. The shaking screen perfectly reproduces the same movement, applied to occasions where particle breakage is prohibited, such as spray drying coffee, powdered products of biopharmaceuticals, powdered milk and metal powder.

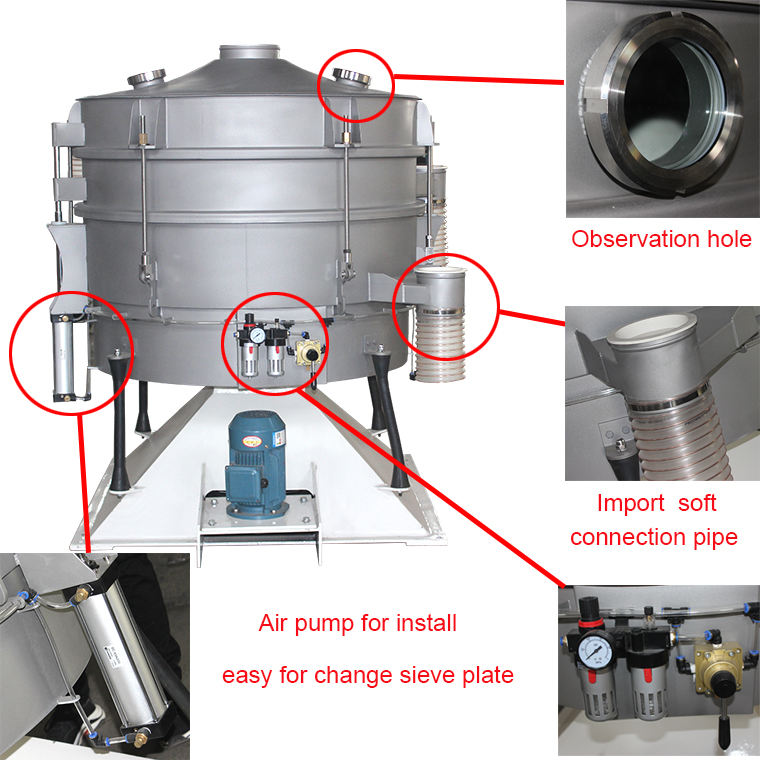

Effectively reduce the maintenance time, as fast as 15 minutes, simple and fast disassembly and installation.

Equipment Parameters

Model | Effective Area | Effective Screen Diameter | Layer | Motor Power | Relevant Dimensions | Cleaning System |

RA-YBS-112 | 1.13 | 1250 | 1--5 | 2.2kw | 1250*1110 | Bouncing ball Rotary brush ultrasonic |

RA-YBS-116 | 1.83 | 1580 | 1--5 | 3kw | 1580/1400 | |

RA-YBS-118 | 2.43 | 1778 | 1--5 | 3kw | 1778/1412 | |

RA-YBS-120 | 2.63 | 1880 | 1--5 | 4kw | 1880/1800 | |

RA-YBS-126 | 5.3 | 2560 | 1--5 | 5.5kw | 2650/1900 |

Engineering case1

Customer site food industry

Zhejiang * * company

Screening material food additive screening 200 mesh specific gravity 0.8 output 400kg

Customer site food industry

Engineering case2

Jiangxi * * company

Sieving material calcium powder sieving 100 mesh, specific gravity 0.9, output 300kg

Our Partners