Working Principle

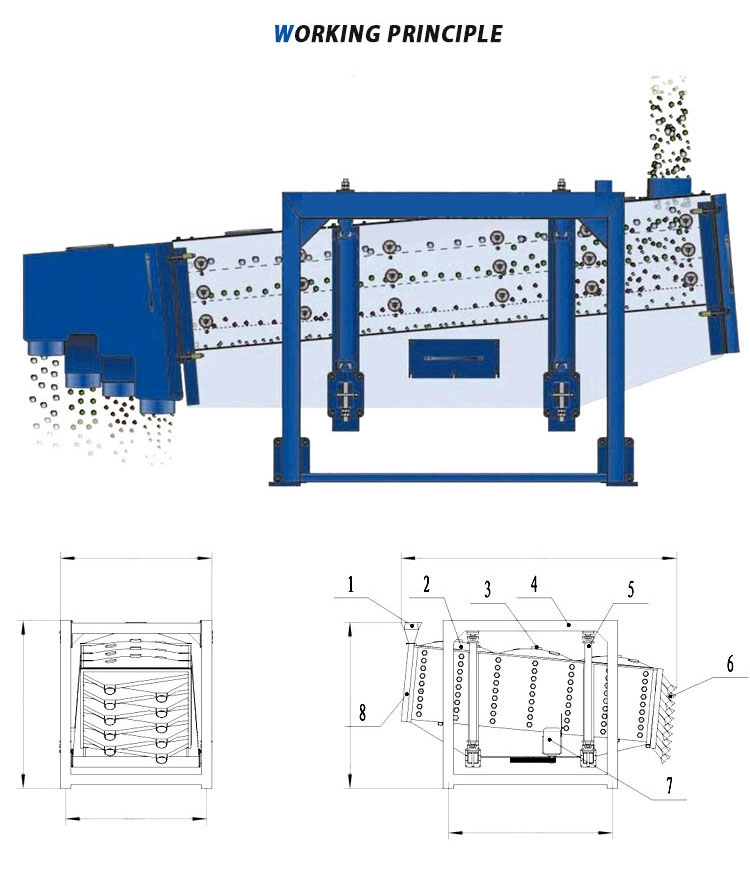

After the swing screen is started, the equipment shaking body, that is, the screen box, reciprocates back and forth under the action of inertial force, and the screen box and the screen surface are conjoined to shake periodically, so that the materials on the screen surface will move in a directional jumping motion together with the screen box.

I. Core Features of the Equipment

1. Alias: Also known as a reciprocating vibrating screen.

2. Vibration Force: Generated by a motor, it is the inertial force of the fixed shaft formed by the rotation of the eccentric wheel.

3. Screen Surface: Horizontal or slightly inclined (R-series equipment has an inclination angle of 0°~5°).

II. Working Principle

4. Start-up and Operation: The screen box (oscillating main body) reciprocates under the action of inertial force.

5. Material Movement: The screen box drives the screen surface to vibrate, causing the material to jump in a directional manner.

6. Screening Process: Material smaller than the screen aperture becomes undersize material; material larger than the screen aperture is discharged after tumbling and jumping.

7. Key Factors: The distance between the eccentric wheels affects the material trajectory and the residence time on the screen surface, thus balancing the throughput and screening efficiency.

8. Practical Suggestions: Balance production capacity and screening efficiency according to actual needs.

Features

1. Using the principle of plane rotation, the distribution of materials on the screen is improved, and the utilization rate of the screen is effectively increased

2. Suitable for cylindrical, flake and other irregular materials, the screening accuracy is as high as 98%, which is several times or higher than that of ordinary vibrating screens

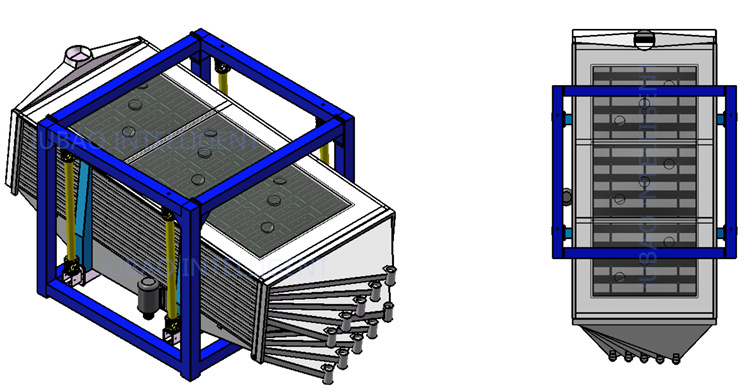

3. It can be used in single layer or multi-layer, and each layer of screen is equipped with a comb-type cleaning device

4. Keeping clean throughout the work process can reduce environmental pollution

Equipment Parameter

Model | Effective screening area(㎡) | Power (KW) | Screen surface inclination(°) | Layer | Rotation frequency(r/min) | Screen box stroke (mm) |

| RA-CFYBS-1030 | 3 | 3 | 5~8 | 1~5 | 180~260 | 25~60 |

| RA-CFYBS-1036 | 3.6 | 4 | 5~8 | 1~5 | 180~260 | 25~60 |

| RA-CFYBS-1230 | 3.6 | |||||

| RA-CFYBS-1236 | 4.32 | 5.5 | 5~8 | 1~5 | 180~260 | 25~60 |

| RA-CFYBS-1530 | 4.5 | |||||

| RA-CFYBS-1536 | 5.4 | 7.5 | 5~8 | 1~5 | 180~260 | 25~60 |

| RA-CFYBS-1830 | 5.4 | |||||

| RA-CFYBS-1836 | 6.48 | 7.5 | 5~8 | 1~5 | 180~260 | 25~60 |