Drum screen is a classic and universal screening equipment. The screen can be selected according to the actual situation. The screen can be arranged in up to four types, and the products of five specifications can be screened at the same time. It is widely used in mining, coke, coal, electric power, building materials, metallurgy, chemical industry and other industries.

Working Principle

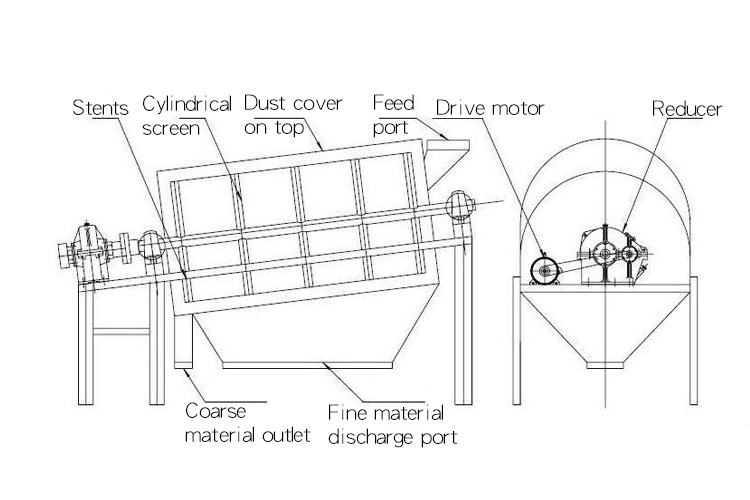

Drum screen is mainly composed of motor, reducer, drum device, frame, sealing cover

and inlet and outlet. The roller device is installed on the frame obliquely. The motor is

connected with the drum device through the coupling through the reducer to drive the

inclination and rotation of the drum device to turn and roll the materials on the screen

surface, so that the qualified materials (products under the screen) are discharged

through the screen of the outer circle of the drum, and the unqualified materials

(products on the screen) are discharged through the end of the roller. Due to the

overturning and rolling of materials in the drum, the materials stuck in the screen hole

can be ejected to prevent the screen hole from being blocked.

Product features

1. The screen hole of drum screen is not easy to be blocked;

2. Stable operation and low noise;

3. Simple structure and convenient maintenance;

4. Drum screen has high reliability and less one-time investment;

5. Special screen is adopted, with high screening efficiency and long service life

Equipment Details

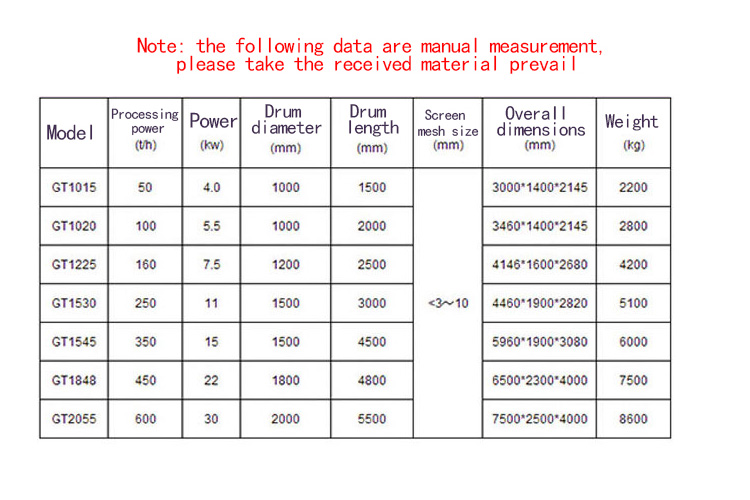

Product Parameter

Case