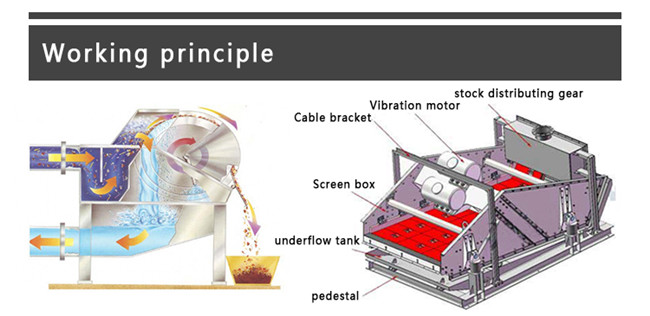

Working Principle

Dehydration screen is mainly used for dehydration, desliming and media removal. It can be used for sand washing in sand and gravel plant, coal slime recovery in coal preparation plant, dry discharge of tailings in concentrator, etc. Therefore, it is also called sand and gravel dehydration screen, mining dehydration screen, coal slime dehydration screen, tailings dry discharge screen, high-frequency dehydration screen, etc.

The dewatering screen adopts double electrode self synchronization technology, which is composed of screen box, vibration exciter (or vibration motor), support system and motor. Two unconnected vibrators are driven by the belt coupling shaft for synchronous reverse operation. The components of the centrifugal force generated by the two groups of eccentric masses are superimposed along the vibration direction and offset by reverse centrifugation, so as to form a single excited vibration along the vibration direction and make the screen box move back and forth in a straight line.

According to the washing and dewatering requirements of different materials, the dewatering screen designs different screen surface inclination and screen plate forms to improve the dewatering production efficiency and ensure the dewatering effect. The dewatering screen can be installed on the left or right according to the location of the production site, which is convenient for the layout of the production process. The dewatering screen dewaters and discharges the tail ore slurry such as coal slime mixed slurry, so as to reduce the energy consumption of the dryer.

Product features

1.Relatively small volume and large processing capacity per unit area, which is convenient for system process layout.

2. Professionally designed frequency, amplitude and low power consumption source are suitable for 24-hour continuous dry drainage operation with various dehydration needs.

3. V-shaped screen surface design, - 5 ゜ screen surface climbing dehydration, dry discharge tailings with low water content and high efficiency.

4. High wear-resistant sieve plate has long service life, modular assembly design and convenient replacement.

5. The combination of riveting and welding of section steel components forms the main body of the frame with no internal stress, high strength, light weight and durability.

Equipment Details

Equipment Parameter

型号 model | 筛网面积Screen area(m³) | 电机功 motor power率(kw) | 处理能力 processing capacity(m³/H) | 进料粒度Feed particle size(MM) | 外型尺 寸Overall dimension(MM) | 重量 weight(t) |

| RA-TSS0720 | 1.4 | 0.75*2 | 5-10m³ | ≤10 | 2300*1000*750 | 0.8 |

| RA-TSS9020 | 1.8 | 1.1*2 | 10-20m³ | 2300*1200*750 | 1.2 | |

| RA-TSS1020 | 2 | 1.1*2 | 10-30m³ | 2300*1300*750 | 1.6 | |

| RA-TSS1225 | 3 | 1.5*2 | 50-80m³ | 2800*1200*800 | 2.1 | |

| RA-TSS1230 | 3.6 | 2.2*2 | 60-90m³ | 3300*1500*800 | 2.6 | |

| RA-TSS1530 | 4.5 | 3*2 | 100-120m³ | 3300*1800*800 | 3.2 |

Case