product description

The vacuum feeder is a new product developed on the basis of widely absorbing

foreign similar products. At present, it is the ideal and perfect vacuum conveying

equipment for powder, granular and powder-granular mixtures in China. It reduces the

labor intensity of workers and solves the problem of dust spillage during feeding. It is

a shou selection equipment for pharmaceutical factories and food factories that have

passed GMP certification and promote clean and civilized production.

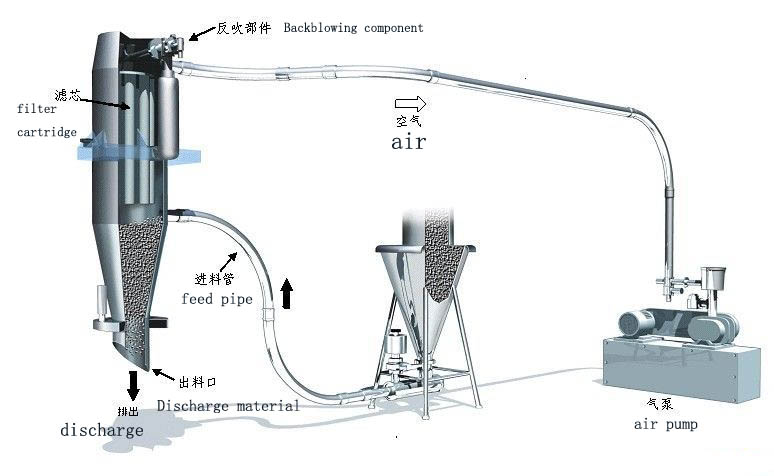

working principle

The negative pressure airflow generated by the vacuum pump and other devices is

used to inhale the material from the feeding port, and the gas and material are

separated in the vacuum feeder. The clean air passes through the filter element and is

discharged into the atmosphere through the vacuum pump, and the material is

separated and falls into the silo. When the feeding time arrives, the vacuum valve is

closed, the unloading valve is opened, the material falls into the designated equipment, and the airbag is blown back to automatically clean the filter element to ensure the

efficient performance of the next cycle. Auxiliary feeding devices such as vibration are

activated to assist feeding. At the end of blanking, it enters the suction state again.

Features

1. Simple: automatic control, the suction and discharge time can be set freely within 0~99 seconds, the operation is simple and convenient;

2. Hygiene: airtight transportation, no dust leakage, no cross-contamination, in line with GMP standards and CIP requirements, and sterile-grade equipment can be provided

3. Fast: easy and fast installation;

4. Cleaning: dust-free operation, eliminating dead ends, quick and convenient disassembly, cleaning and refueling;

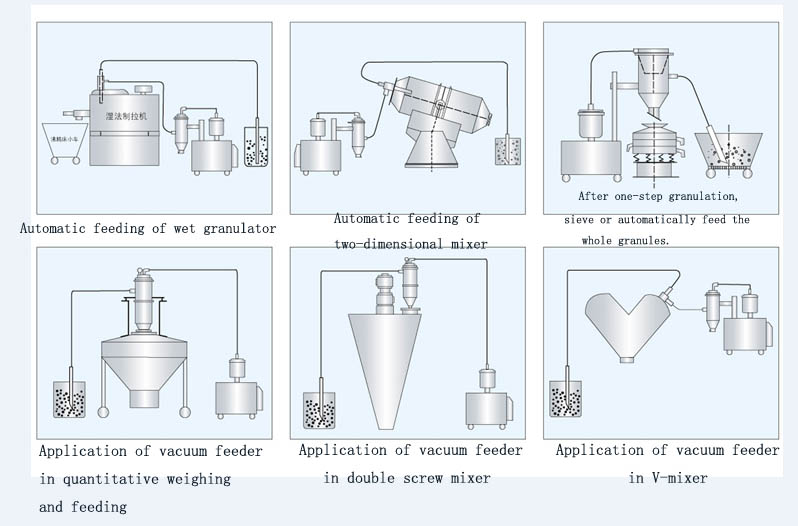

5. Economical: One machine can be used on multiple sets of equipment in turn, with high efficiency and energy saving, no need to warm up and stand by, and low operation and maintenance costs;

Product details

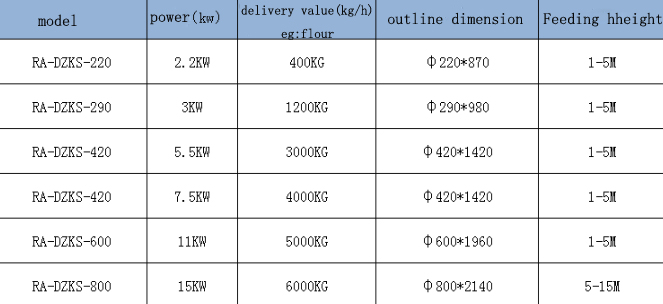

Technical parameter