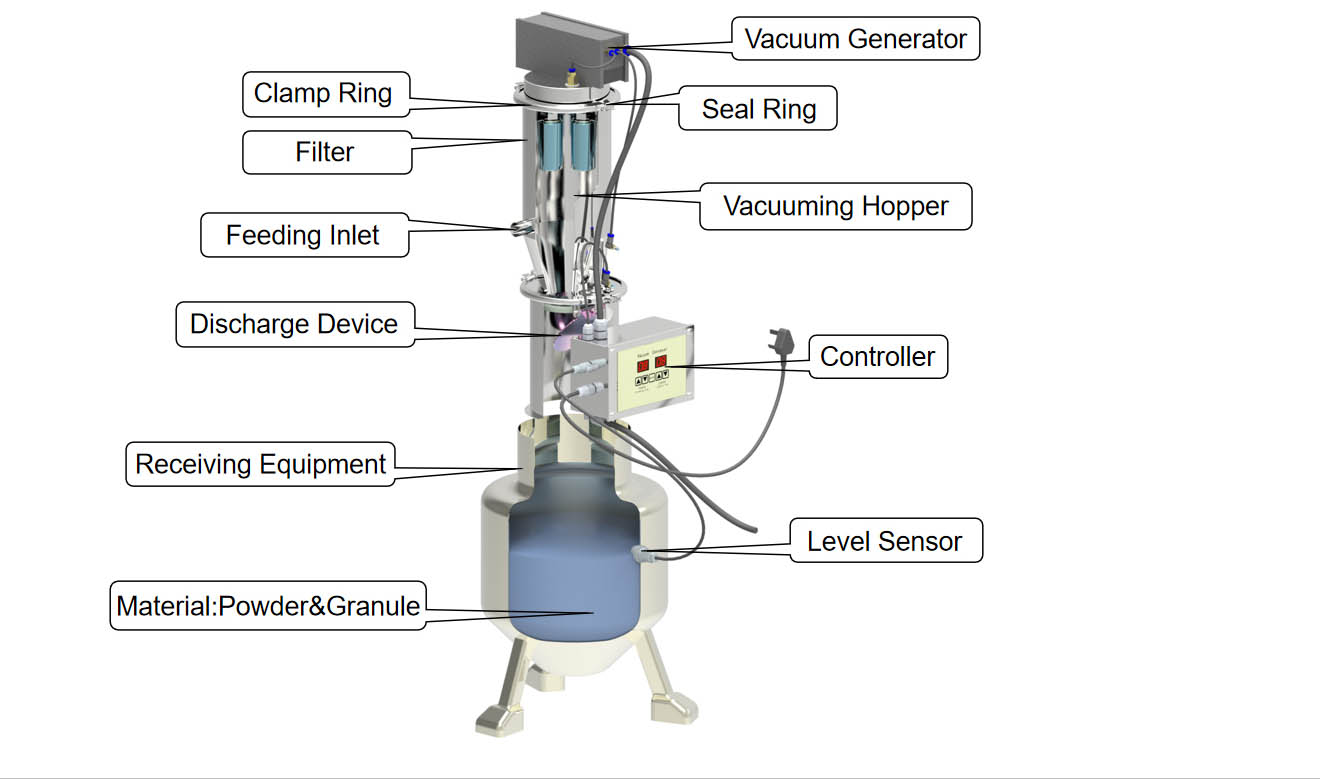

Product Description

Pneumatic vacuum feeder uses compressed air & vacuum generator to create high vacuum for material conveying, no mechanical vacuum pump required. It eliminates material layering, ensures uniform composition of mixed materials, and is ideal for automatic machinery feeding.

Working Principle

Supply compressed air to the vacuum generator → negative pressure forms vacuum airflow.

Materials are sucked into the nozzle to form a material airflow, then transported to the feeder silo via the suction pipe.

The filter separates materials from air completely.

When the silo is full → controller cuts off air source, vacuum generator stops, silo door opens automatically, materials fall into the equipment hopper.

Meanwhile, compressed air cleans the filter via the pulse backflush valve.

The feeder restarts automatically when the preset time is up or the material level sensor sends a feeding signal.

Features

Quick connector, easy to disassemble, small in size, simple in operation, and does not take up space

Powered by compressed air, no electricity, no electrical interference, no electrical hidden dangers

The conveyed material eliminates the phenomenon of stratification and ensures the identity of the material composition.

No vibration, low noise, equipped with automatic backflushing system, automatic cleaning

Airtight conveying, no dust leakage, no cross-contamination

Product Details

Equipment Parameter

| Model | Gas consumption (M³/min) | Gas supply pressure (Mpa) | Conveying energy (kg/h) eg:flour | Outline dimension | Feeding height |

| RA-QZKS-190 | 0.28 | 0.5-0.8 | 100KG-300K | φ190*800 | 1-5M |

| RA-QZKS-220 | 0.46 | 0.5-0.8 | 200KG-500KG | φ220*870 | 1-5M |

| RA-QZKS-290 | 1.29 | 0.5-0.8 | 500KG-1000KG | φ290*980 | 1-5M |

| RA-QZKS-420 | 2.7 | 0.5-0.8 | 1000KG-2000KG | φ420*1420 | 1-5M |

| RA-QZKS-600 | 3.8 | 0.5-0.8 | 1000KG-3000KG | φ600*1960 | 1-5M |