I. Product Description

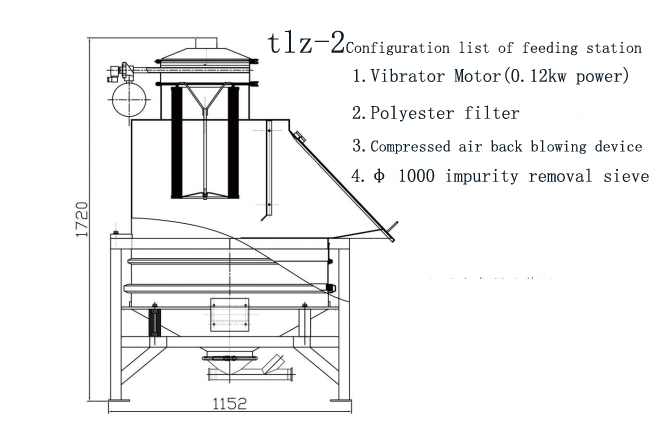

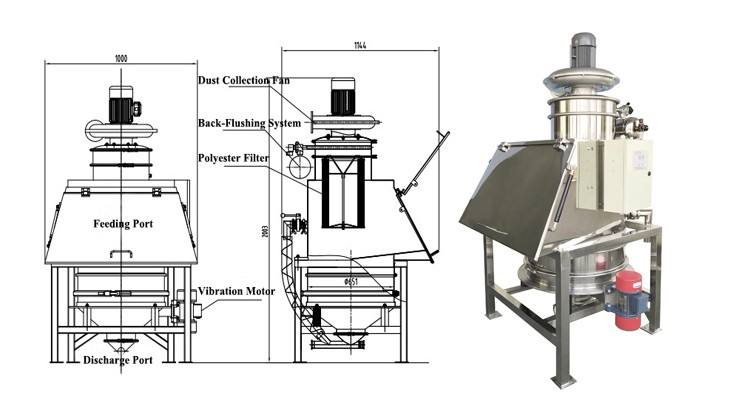

1. Core Function: For 0-50KG small-packaged materials, manual unpacking and feeding are achieved. Dust is eliminated throughout the process via filters and dust collectors, ensuring zero dust leakage.

2. R&D Basis: Developed by extensively absorbing technologies from similar foreign products.

3. Applicable Materials: Powdered, granular, and powder-granular mixtures; currently the most advanced vacuum conveying equipment.

4. Core Value: Reduces labor intensity for workers, solves the problem of dust spillage during feeding; assists pharmaceutical and food factories in obtaining GMP certification, promoting clean and civilized production.

II. Working Principle

1. Feeding Process: After manual unpacking, the material is automatically tilted, falling into the storage hopper by gravity, completing the unpacking and unloading process.

2. Dust Removal Mechanism: The equipment has a built-in filter cleaning device and exhaust fan to filter dust generated during the tilting process. Clean exhaust gas is discharged into the atmosphere, ensuring a clean working environment.

Features

1. Reduce manual heavy manual labor;

2. No dust flying, sanitation and environmental protection;

3. Small filtration precision, no waste or loss of materials;

4. Effectively connect with the next process;

5. It can be equipped with automatic cutter and bag pressing device;

6. Small size, can move freely, and has a wide range of applications.

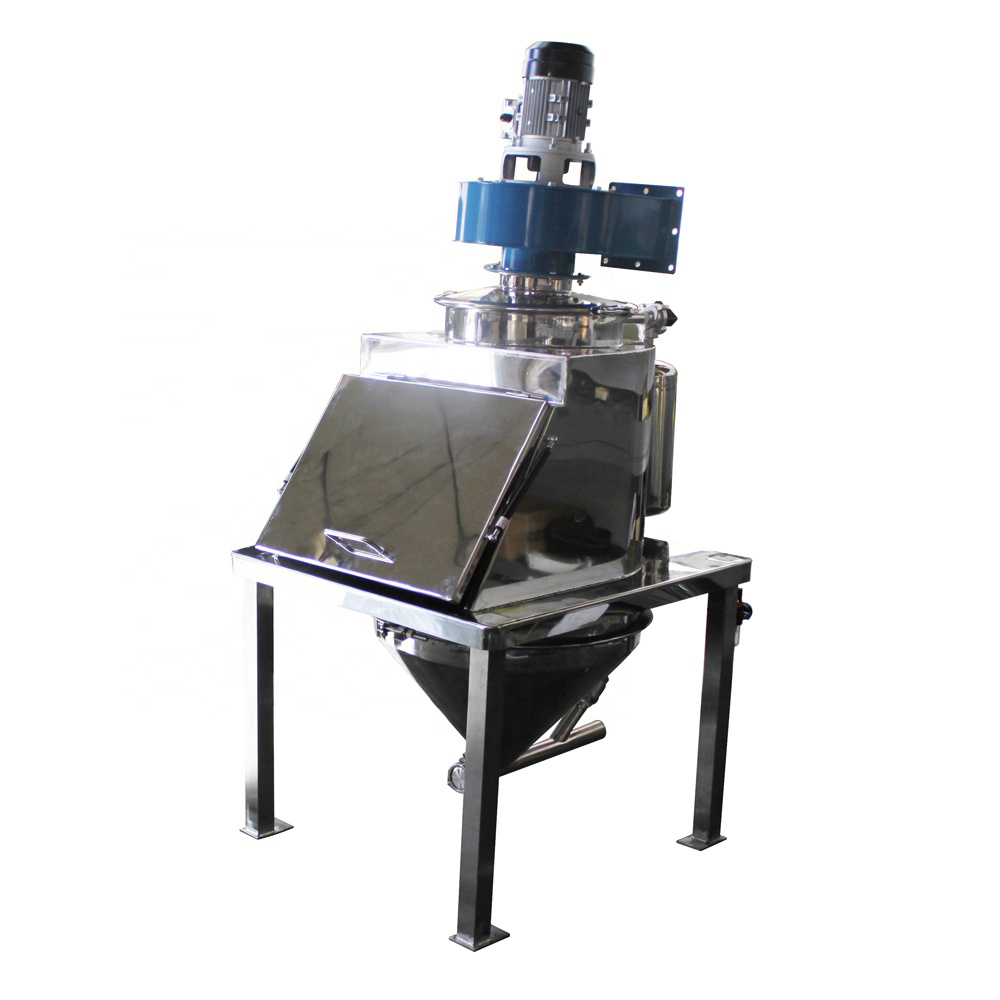

Equipment Details